Introduction

In the realm of manufacturing and quality control, testing bursting strength is a crucial component. It ensures that products can withstand a certain level of pressure during use,. To guarantee the accuracy and reliability of these tests, let's delve into the bursting strength test method.

Part 1: Understanding fabric bursting strength tester

|

Model |

GT-C12B |

|

The min. division value |

0.002Mpa |

|

Test area |

7.3 cm2 (Φ30.5mm), 10 cm2 (Φ35.7mm), 50cm2 (Φ79.8mm), 100 cm2( Φ112.8mm) can be option |

|

Pressure speed |

100ml/min - 500ml/min |

|

Accuracy |

±1 mm, when the height at burst up to 70 mm |

|

Output |

Printer, display output, and can be connected to the computer |

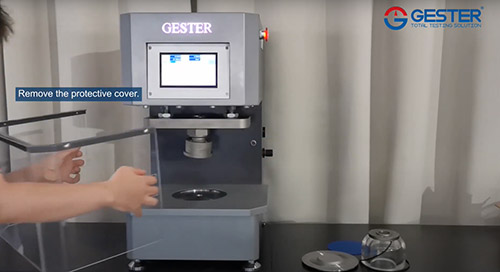

3. Safety Measures: Implement the necessary safety precautions for you and your team to minimize the risk of accidents.

Power On

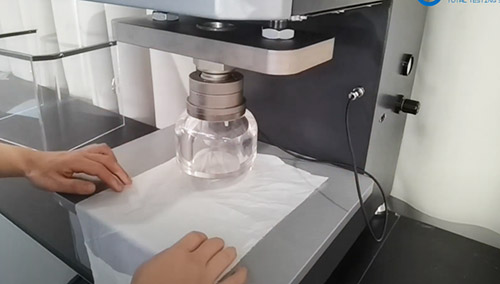

2. Installation: Installation of the lower fixture: first install the aluminum block, then place the rubber diaphragm, which is divided into positive and negative, the smooth is side up, and finally place the lower pressure plate.

Installation

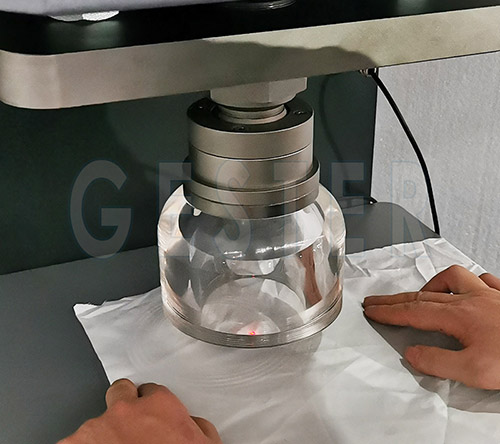

3. Sample Placement: Securely fix the sample you intend to test, ensuring it's properly aligned and tensioned.

Sample Placement

4. Setting Parameters: Enter the setting interface to set the test parameters: set the initial test speed, select the suitable fixture, other parameters can not be modified, because it is set in accordance with the standard.

Setting Parameters

5. Test Initiation: Start the formal test. Place the sample and clear the data and click '' Test''. The result will be displayed after the test is finished. You can decide how many tests to do depending on your needs, and the test result will be displayed after the bursting strength of fabric test.

Test Initiation

Data Analysis

Conclusion