|

Table of Contents: |

|

-Introduction -Understanding the Xenon Weathering Test Chamber 1. Preparing the Test Samples 2. Setting Up the Test Parameters 3. Running the Weathering Test 4. Analyzing the Results - Conclusion |

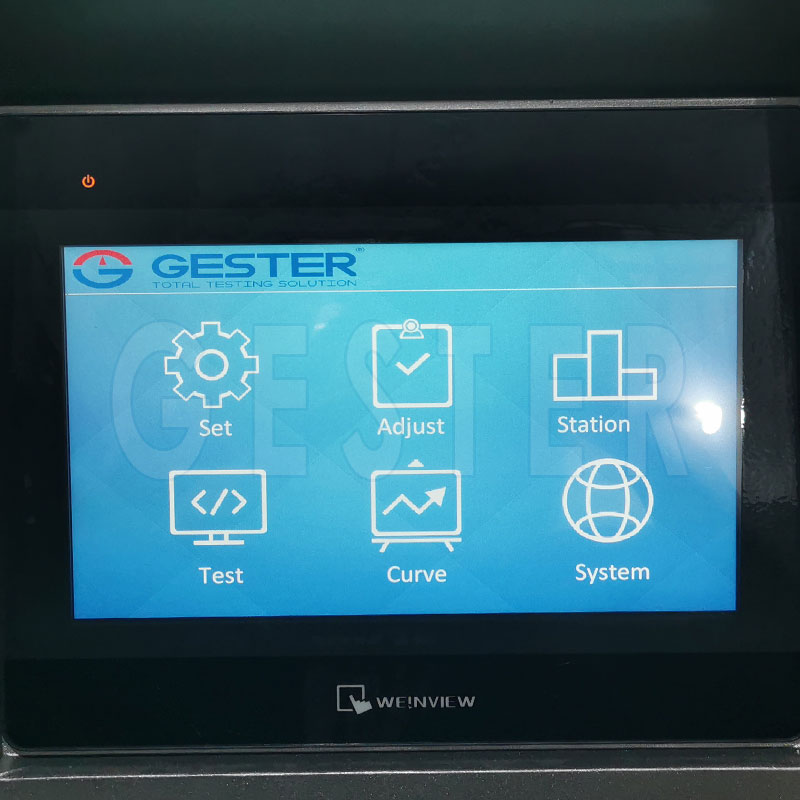

Once the test parameters are set, it's time to run the weathering test. Start the Color Fastness To Light Machine and ensure that the specified conditions are maintained consistently throughout the test duration. Monitor the samples periodically to assess the changes in color, texture, or any other physical properties. Note the duration of the test to calculate the equivalent real-time exposure.