I. Introduction

II. Preparation

III. Operational Steps

IV. Maintenance and Cleaning

Ⅴ. Conclusion

Table of contents

I. Introduction

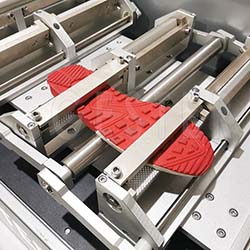

The EN Sole Flexing Tester is a professional device used to assess the flexibility of shoe soles, simulating bending conditions during usage to evaluate durability and quality. Proper execution of its operating procedures is crucial for ensuring accurate test results. This article will detail the operational steps of the sole flexing tester, enabling users to conduct tests correctly and efficiently.

III. Operational Steps

12:Clear the current data, set the number of tests. Then start to test.

13:The machine will stop automatically when it runs up to the set numbers.

|

|

|

IV. Maintenance and Cleaning