|

Table of Contents: |

|

1. Introduction 2. Working Principle 3. Key Features 4. Applications 5. Conclusion |

Introduction

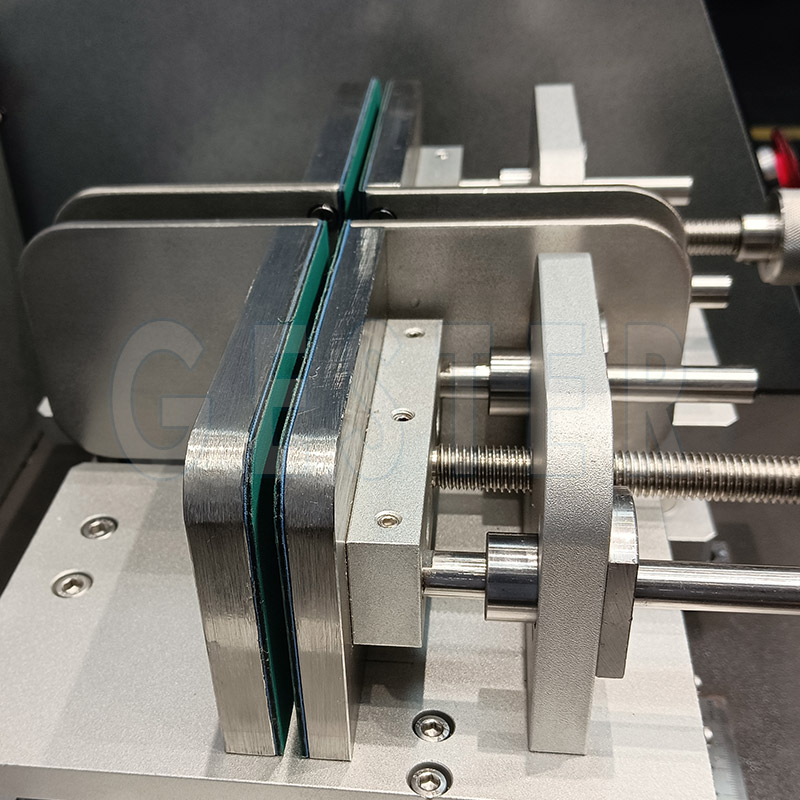

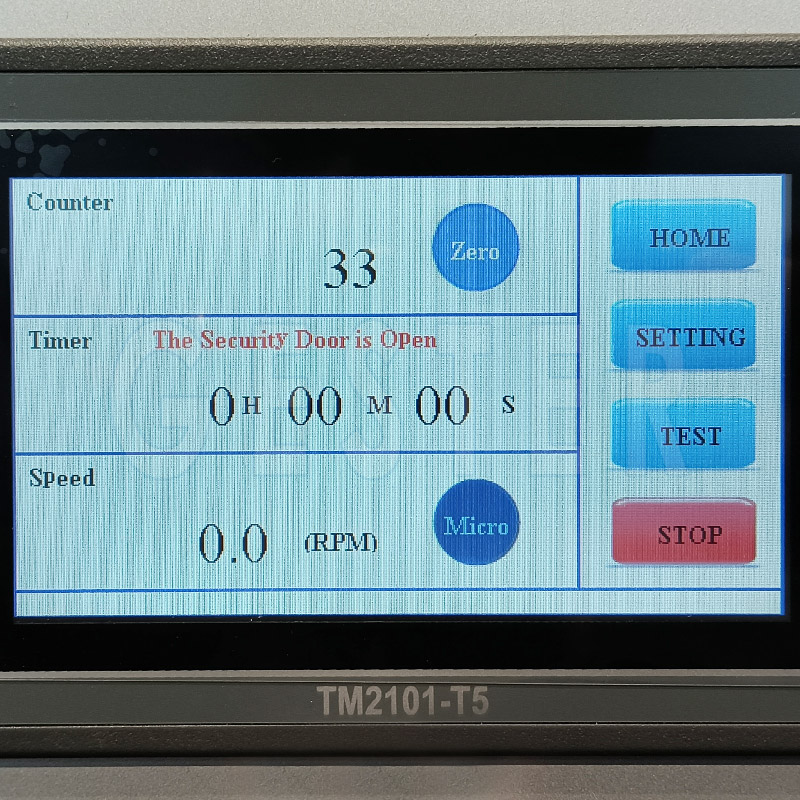

A Belt Dynamic Durability Tester is a specialized testing equipment designed to assess the durability and performance of various products such as belts, straps, bags, and soft belt handles. By subjecting these specimens to repetitive flexing movements and bending forces, the tester simulates real-world usage scenarios and helps evaluate the endurance and quality of the tested items.