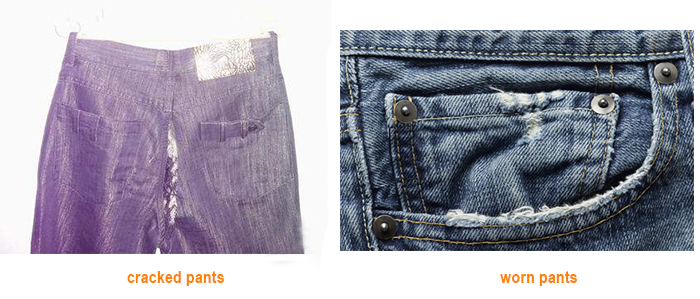

The common problem of cracking of trousers and apparel products is that the tension is large during people's wearing, especially when they are squatting, and they are often in a tortuous state. Many clothing companies have encountered market complaints due to cracked pants and worn pants.

So how did this happen? How to control quality?

Analysis of the causes of cracking of pants

The reason for the cracking of the pants can be attributed to three categories.

The first category: the poor of fabric breaking strength and tear strength.The mainly reason is that the clothing companies do not strictly control the indicators of product strength, as long as the strong standards are controlled, they can be avoided.Every clothing companies can test sample all kinds of material in the process of manufacturing finished garments.

The second category: poor wear resistance.The breaking strength and tearing strength of this kind of fabric can reach the national standard, but the fabric is cracked after repeated bending and wear of the fabric during the wearing process, but the consumers wear fabric in the process of repeated twists and wear cause the phenomenon of cracking.

The most typical denim fabric, its breaking and tearing strength must meet the requirements of FZ/T 81006-2007 "Jeanswear". During the wearing process, the pants fabric is first worn and then cracked, especially the polyester-cotton interwoven jeans which are dealt by resin. The resin dealing causes the abrasion resistance of the fabric to decrease, resulting in serious wear.

In addition to jeans fabrics, there is also a class of chemical fiber interwoven fabrics that are easily overlooked by apparel manufacturers. These fabrics all contain chemical fibers. Because the chemical fiber strength is generally high, it will cause an illusion when tested, and the tearing and breaking strength is very high. In fact, this is because of the high-strength chemical fiber support. The strength of the fabric is poor, such as cellulose fiber cannot be reflected. This situation leads to mass accidents that occur during wear.To test the quality of such fabrics, only focus on breaking strength and tearing strength can not be effectively controlled, but also to increase the wear resistance test.

The third category: yarn slippage at the seam of the crotch.These fabrics can reached national standards in all aspects,even exceed it. But the yarn can easily slip off the seam, causing cracking.

Cracking remedies and precautions

In the dyeing production and the washing process of finished pants, a large amount of softener is added in order to improve the feel of the pants. However, this process exacerbates the slippage cracking and need cracking inhibitor to for remedy for that. The cracking inhibitor is a high molecular polymer which increases the surface friction coefficient of the yarn and improves the slip of the fabric.

Nevertheless, this method is an after-the-fact remedy, increasing costs, time and effort, and the fundamental way to solve the problem is to strictly control beforehand is the best practice.

In the process of production, the fabric is tested for breaking strength, tear strength and abrasion resistance.

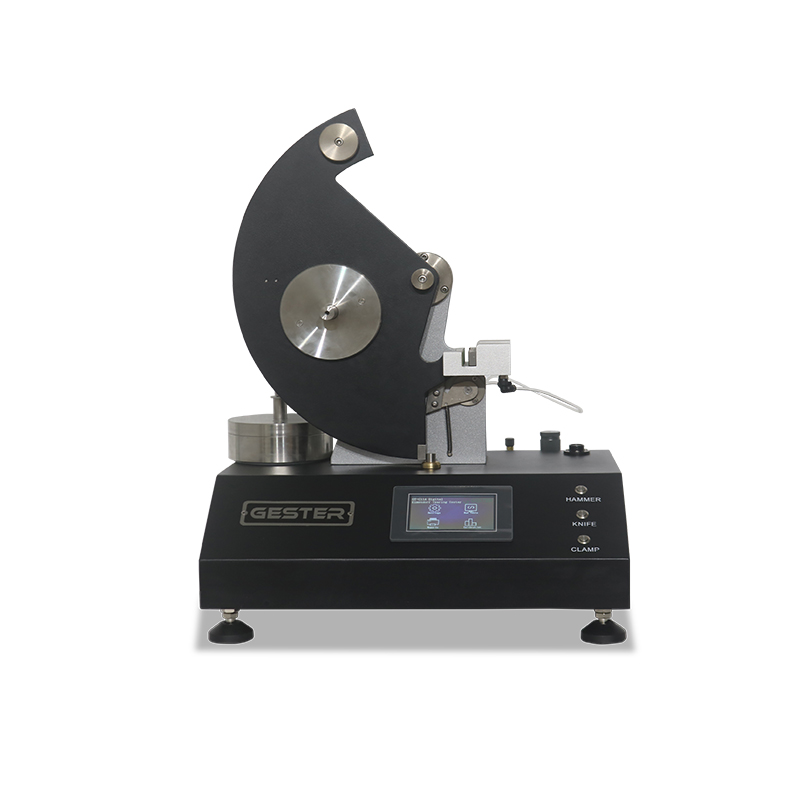

Gester Instruments Co.,LTD is professionally engaged in production and R&D of physical properties testing equipment. With nearly 20 years experience in research and development,we specialize in providing the total solutions of Textiles Testing Equipment.

Textile Testing Equipment include: Abrasion Tester, Pilling Tester, Tensile Tester, Fastness Tester,Tearing Tester ,Bursting and Flammability Tester.