Balance is a commonly used equipment in laboratory. How to use balance correctly has an important influence on the accuracy of experimental data.

As the precise instruments, if we can operate and maintain it well, then will keep the live of balance.

01 Relative terms

02 scale grade

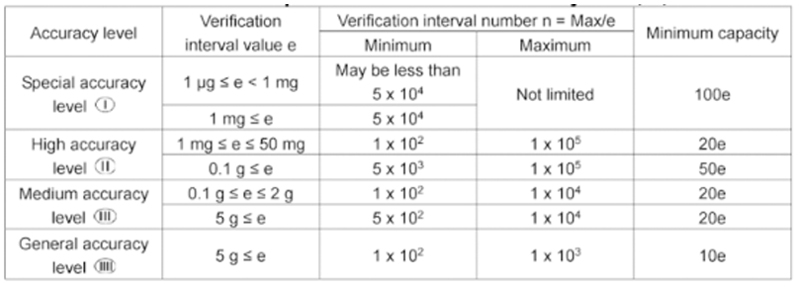

The balance is divided into four grades according to the verified degree value e and the verified degree n. Meanwhile, the accuracy level of the balance also meets the corresponding relationship with e and n, as shown in table 1.

Table 1 relationship between balance accuracy level and e and n

Note: in the last column of the above table, except for the special accuracy grade balance with e < 1mg, d is used to calculate the minimum weight in place of e.

03 Balance error

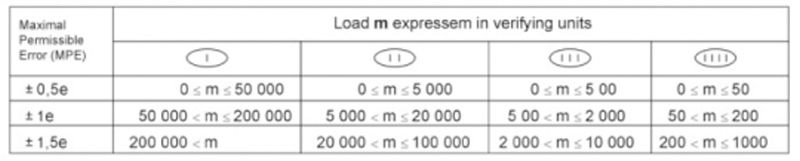

Different scales have different maximum allowable errors (MPE), and the same scale has different maximum allowable errors in different scales. The relationship between the maximum allowable error and the scale level and weighing range is shown in table 2.

Table 2 relationship between the maximum allowable error and balance level and weighing range.

Application notice:

1. Observe the level device of the balance and check whether the balance is level. Balance of balance can be adjusted by adjusting the foot bolt of balance.

2. After power failure for a long time, start the machine for preheating for 30min. If no power failure occurs, start the machine directly for use.

3. Open the windproof cover of the balance, put it into the weighing paper, and after the indication is stable, press the "clear zero" button to close the windproof cover, and observe whether the indication of the balance is zero. If not, press the "clear zero" button until the indication is zero.

4. Open the windproof cover, put the articles to be weighed on the balance, close the windproof cover, and read the indicator number after the indicator number of the balance is stable.

The constant weight weighing method is to select any object block whose mass will not change easily, such as weight, weight block, iron block, etc. After the balance is measured, the measured balance is used to weigh and take the block for many times, and the average value is taken and recorded. This value defaults to the mass of the block. Take good care of the object block to prevent it from damp wear. During the verification, the scale is used to weigh the block and record the value. The value is compared with the mass of the block and the maximum allowable error in table 2 is considered to be stable.

It should be noted that when selecting the block, the maximum allowable error of the balance should be covered by the weighing range.For example, for a high-accuracy grade balance, d=0.001g, e=10d, the maximum weight is 220g, the maximum allowable error is 0.005g when 0 m 50g, the maximum allowable error is 0.010g when 50 < m 200g, and the maximum allowable error is 0.015g when 200 < m 220g.Therefore, three blocks should be selected, with a mass of 0 ~ 50g, 50 ~ 200g and 200 ~ 220g respectively.This ensures that the scales are checked periodically for each scale range.

This method has the advantages of low cost, convenience and easy operation

Balance is a kind of precision instrument, which needs not only maintenance in daily use, but also regular maintenance

Application notice:

1. In the daily weighing, don't spilled the liquid into the internal balance, if accidentally sprinkle, sort out in a timely manner.

2. After each use, clean up the balance scale, to prevent debris into the internal sensor scales.

3.regular maintenance, all stainless steel parts to clean, remove the balance scale thoroughly clean, do not use corrosive cleaner to remove scale, with washing ears ball or small brush inside clean up dust and debris, scale and parts after drying, the installation.

4. Adjust the balance level, start the machine, adjust the balance, and check whether the balance runs normally. If the balance has self-calibration function, it can be self-calibrated.

Gester Instruments Co.,LTD is professionally engaged in production and R&D of physical properties testing equipment. With nearly 20 years experience in research and development,we specialize in providing the total solutions of Toys Testing Equipment, Textile Testing Equipment and Footwear Testing Equipment.