Share GESTER's Takeaways from the ITMA ASIA + CITME 2022 Exhibition

November 27, 2023

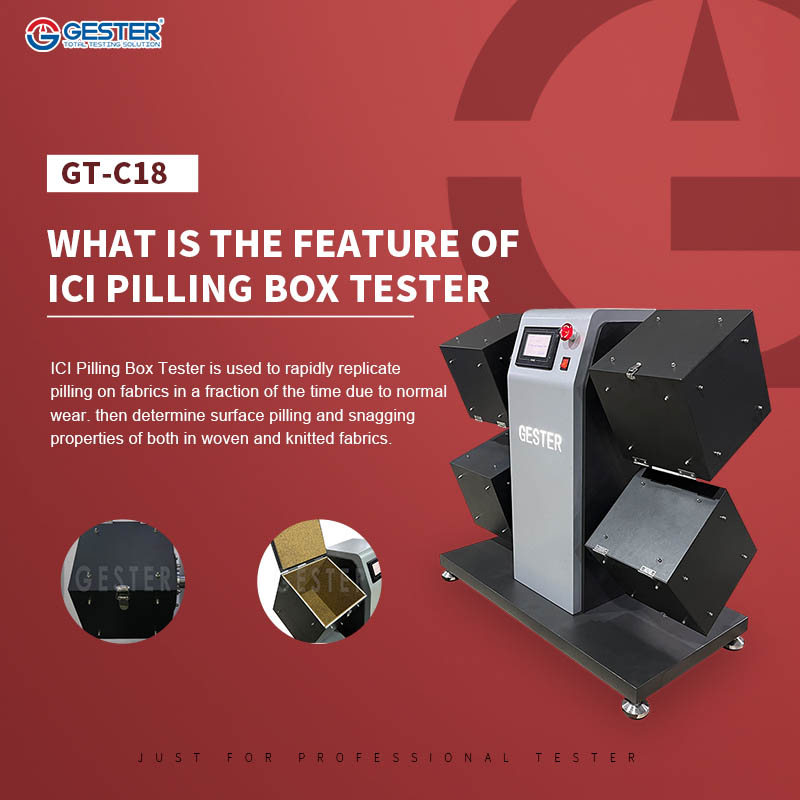

Share GESTER's Takeaways from the ITMA ASIA + CITME 2022 Exhibition Introduction In November 2023, GESTER's professional team had the privilege of participating in the ITMA ASIA + CITME 2022 Exhibition at the National Exhibition and Convention Center in Shanghai, China. The event, spanning from November 19th to 23rd, served as a prominent showcase for advancements in the textile machinery industry. The ITMA ASIA + CITME 2022 Exhibition brought together global interested parties and professionals, offering a comprehensive overview of the latest innovations in textile machinery. GESTER, positioned at Booth NO.H8A54, actively contributed to the event's vibrancy by demonstrating our commitment to excellence in textile testing equipment, emphasizing precision and quality in our offerings. I. Exhibition Highlights and Insights Our team's participation in the ITMA ASIA + CITME 2022 Exhibition proved to be a rich source of new insights and invaluable experiences. Amidst the bustling atmosphere of the event, our members had the opportunity to delve into various aspects of the textile machinery industry, gaining a deeper understanding of its intricacies. In line with the dynamic nature of the industry, our team keenly observed and absorbed the latest trends. The exhibition served as a window into the forefront of technological advancements, allowing us to stay abreast of innovations that are shaping the future of textile machinery. The firsthand exposure to emerging technologies and methodologies has provided our team with a nuanced perspective. II. GESTER's Exhibition Highlights A. Showcasing Key Products and Technologies that Captivated Attention Our presence at ITMA ASIA + CITME 2022 attracted a lot of attention, mainly because of the advanced features, reliability and comprehensiveness of our quality equipment. The GT-C01-1 Universal Tensile Strength Tester stood out for its multifunctionality, conducting an array of tests for various materials. Its adaptability for rubber, plastic, metal, fabric, and more drew attention. The martindale abrasion and pilling tester GT-C13B is used to determine the abrasion and pilling resistance of all kinds of textile structures. The excellent testing capabilities of this machine, coupled with the unique patents of our equipment, make it the most popular product. The GT-C12 Bursting Strength Tester, designed for woven, knitted, and non-woven fabrics, papers, and boards, was a showstopper. Of great interest to industry professionals, this burst test equipment use hydraulic method, meet multinational standards and equipped with several changeable test clamp. Our showcase further included the GT-C27 Automatic Air Permeability Tester, a testament to our commitment to precision testing. This equipment's proficiency in assessing the air permeability of various fabrics and filter materials resonated well with industry professionals. The GT-D04 Electronic Crockmeter applicated in determining the color fastness of textiles to d...

View More