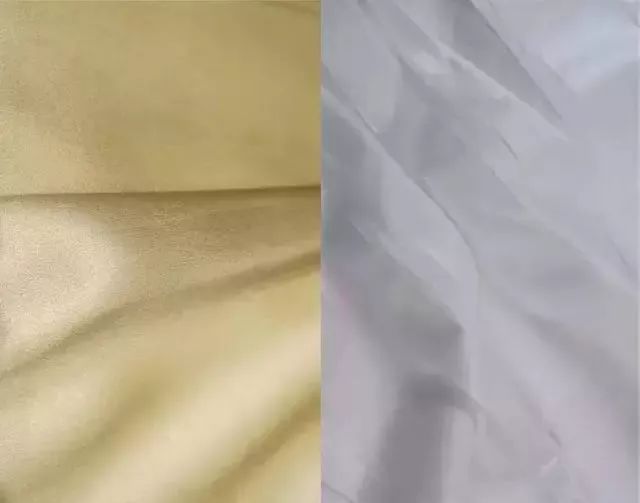

“Yellowing” refers to the surface of the white or light-colored substances become yellow under light, heat or chemicals impact. The yellowing phenomenon not only damage the appearance of the white, but also shorten it’s lift time greatly.

White or light-colored textile made of nylon and elastic fibers as well as related combination fabric will become yellow easily. “Yellowing” will happens everywhere, such as the dyeing and finishing process, storing or hanging in the showcase or even at home. There’s many reasons which may cause “yellowing”, like the material itself may become yellow easily, or the chemicals used on the fabric (residual oil or softener)may become yellow easily too.

Normally, we need to do further analysis if we want to know the real reason that the textile become yellow. Such as how to setting the processing conditions, which chemicals can be use or can not be use, which reasons may have coefficient effects on textile and how to packing and storing the textile.

Reasons for fabric yellowing:

(Gas fading):

——Shaping machine NOx fumes

——NOx fumes during storage

——Exposure to ozone

(Temperature):

——Heat Sizing

——High temperature die-cast

——Softeners and high temperature processing

(Packaging&Storage):

——Phenol and amine related yellowing sunlight

—— Dye and Fluorescent Fading

—— Fiber degradation

(Micro-organisms):

—— Suffered from the destruction of bacteria and mold

(Miscellaneous):

—— The relationship between softener and fluorescein

Source analysis of the problem or countermeasures:

Setting Machine

There are many setting machines can be applied in textile industry. Such as heat by burning gas or oil directly. Machines heating by this way may product NOx which is harmful.

In order to avoid surplus NOx when sizing the the specimen. We can use GESTER Laboratory HT Steamer Stender-Vertical Type GT-D21B when specimen sizing.

Ozone fading

This may usually happens in apparel industry. Some softener may make the textile yellowing because of the Ozone. Special ozone resistance softener may reduce this problem.We can use GESTER Colorfastness to Ozone GT-D01B to imitate the Ozone environment.

High Temperature

Textile will become yellow because fiber oxadate, lubricant on the fiber and textile or impurity on the fiber effected by high temperature. And this may cause during the stamping procedure of synthetic fabrics (especially girs’underwear like PA/EL bra) .GESTER GT-C52 Programmable Temperature & Humidity Test Chamber can help you when having the test.

Sunlight

Generally speaking, the light fastness of fluorescent brightener is poor. Fabrics with fluorescent brightener may become yellow easily if exposure under the sunshine for a long time. So we suggest to use high light fastnees fluorescent brightener if the fabrics is strict on quality. Sunlight, as a kind of energy, will let the fiber regression. Glass can’t filter out all the UV (can only filter light wave lower than 320nm). Nylon is easy to become yellow, especially half matt gloss or dark fiber with pigment. Fiber with high moisture may make the problem worse. We can use GESTER GT-D02A-1 Light Fastness Tester- Room Temperature (Air-Cooled) to imitate the sunniness.