Everyone is familiar with clothes pilling, believe that many people have met clothing pilling after wearing a period of time. Pilling is one of the important factors which affect the feeling, appearance and wear performance of the fabric.

So where does it come from? What kind of cloth will get pilling easily? How does the laboratory test and evaluate the pilling performance of clothing?

Where does it come from?

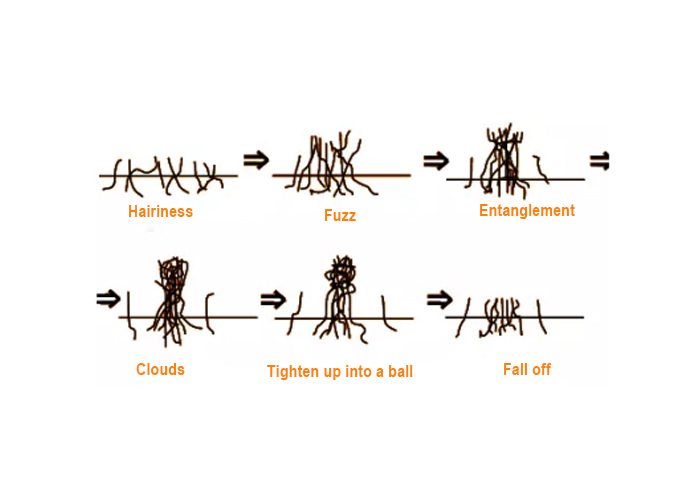

The fabric being constantly friction while using, so that the surface fiber ends been pulled by dragged, hooked and pulled out, and the phenomenon of forming hairiness on the fabric surface was called fluffing. As the hairiness is gradually extracted and extended, generally more than 5mm, and then bearing the friction, these fiber ends will hook each other, winding to form an irregular spherical phenomenon known as pilling. As the fabric continues to rub, the fiber balls gradually become closer and the fibers attached to the fabric are subjected to repeated bending, fatigue and even fracture in different directions. The fiber balls then fall off the fabric surface, but the fiber hairs at the end of the fracture will continue to be pulled out in use and form the fiber balls again.

Why does it pill?

The continuous mechanical action such as friction and hook during the wearing or washing of clothes causes the pilling of clothes.

What kind of cloth will get pilling easily?

How does laboratory test pilling performance?

Principle and instrument:

Surface Fuzzing and Pilling Tester

The sample is rubbed with nylon brush and fabric abrasive or only with fabric abrasive on a specified number of times under specified pressure to make the surface of the sample pilling. The method is fast and can simulate the tripping and pilling of the fabric. It is suitable for the knitted fabric such as garment and T-shirt.

Martindale Abrasion and Pilling Tester

Under specified pressure, the circular sample rotates freely around the center axis perpendicular to the plane of the sample, and the trajectory of the lizaru figure is rubbed with the same fabric or wool fabric abrasive. Suitable for bed category testing.

ICI Pilling and Snagging Tester

The sample installed on the polyurethane tube is flipped randomly in a wooden box with constant rotation speed and lined with cork. After a specified number of turns, the pilling and/or pilling performance is evaluated visually. Applicable to the testing of sweater - like textiles.

Random rolling pilling is used to make the fabric tumble and rub randomly in a cylindrical test chamber lined with cork gaskets and a small amount of grey short cotton.

The above test methods are designed to simulate the process of taking the product. However, due to the complexity and diversity of pilling process and the situation of taking the product, the result of the test is often not consistent with the effect of wearing. Therefore, in addition to using the test, it should be judged by comparing with the effect of trying on the product.

Gester Instruments Co.,LTD is professionally engaged in production and R&D of physical properties testing equipment. we specialize in providing the total solutions of Toys and Baby Stuff Testing Equipment, Textiles & Garments Testing Equipment and Footwear Testing Equipment.