Multi-angle Analysis Yarn Twist

June 16, 2021

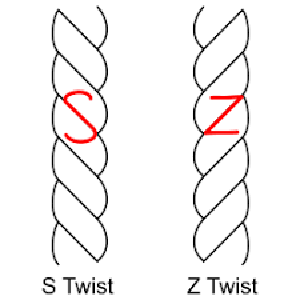

1. About yarn Yarn is a long continuous length of interlocked fibres, suitable for use in the production of textiles, sewing, crocheting, knitting, weaving, embroidery, or ropemaking.A generic term for yarn and thread, it is a long, thin, soft and continuous strip with a certain strength, it is made of textile fibers, including single yarns and ply yarn. 2. What is the twisting? Fibres are arranged around an axis by means of twist. Twisting adds strength to the yarns. Twisting, in yarn and rope production, process that binds fibres or yarns together in a continuous strand, accomplished in spinning or playing operations. The direction of the twist may be to the right, described as Z twist, or to the left, described as S twist,including. 3.The following four parameters are of importance when discussing twist in yarn: A. Direction of twist B. Twist level/ Amount of twist C. Twist angle D. Twist multiplier 4. Twisting process A. Single yarn Single yarn is formed by twisting fibres or filaments in one direction. B. Ply yarn Ply yarn is made by twisting two or more single yarns together, usually by combining singles twisted in one direction with a ply twist in the opposite direction. It is stronger and more resistant to abrasion than single yarns. Twine, cord, or rope can be made with a cable twist, each twist in the opposite direction of the preceding twist (S/Z/S or Z/S/Z), or with a hawser twist, the single yarns and the first ply twist in one direction and the second ply twist in the opposite direction (S/S/Z or Z/Z/S). The number of turns per unit of length in a yarn affects the appearance and durability of fabric made from that yarn. Yarns used for soft-surfaced fabrics have less twist than those used for smooth-surfaced fabrics. Yarns made into crepe fabrics have maximum twist. 5.EXPRESSION OF TWIST Amount of twist expressed in 1) Twist Per Inch(TPI) 2) Twist Per Meter(TPM) 3) Twist Per Centemeter(TPC) TWIST FACTOR OR TWIST MULTIPLIER The twist factor or twist multiplier is a measure of twist, which accounts for the yarn radius as well as the twist level. TM=TPC√tex or TM=TPI÷√Ne 6. FACTORS AFFECTING TWIST The twist introduced in the yarn during spinning depends upon a number of factors, such as follows: A. The count of yarn to be spun B. The quality of cotton used C. The use to which the yarn is put- is the yarn meant to be used as warp yarn or weft yarn, knitting yarn or any other yarn. D. The fineness of the fibre being spun F. The softness of the fabric into which the yarn is to be converted 7. YARN TWIST In practice, yarn twist is described using three main parameters: (a) twist direction (b) twist factor or twist multiplier And (c) twist level (turns/unit length). 8. Function of twist in yarn structure: A yarn must have sufficient tensile strength to withstand the stresses of preparation and fabric manufacture. Without twist a strand of fibers has very little strength. . The main function of twist is to be bind the fibers together and help...

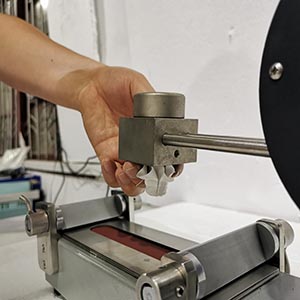

View More