Some Common Sense of Shoes

April 29, 2019

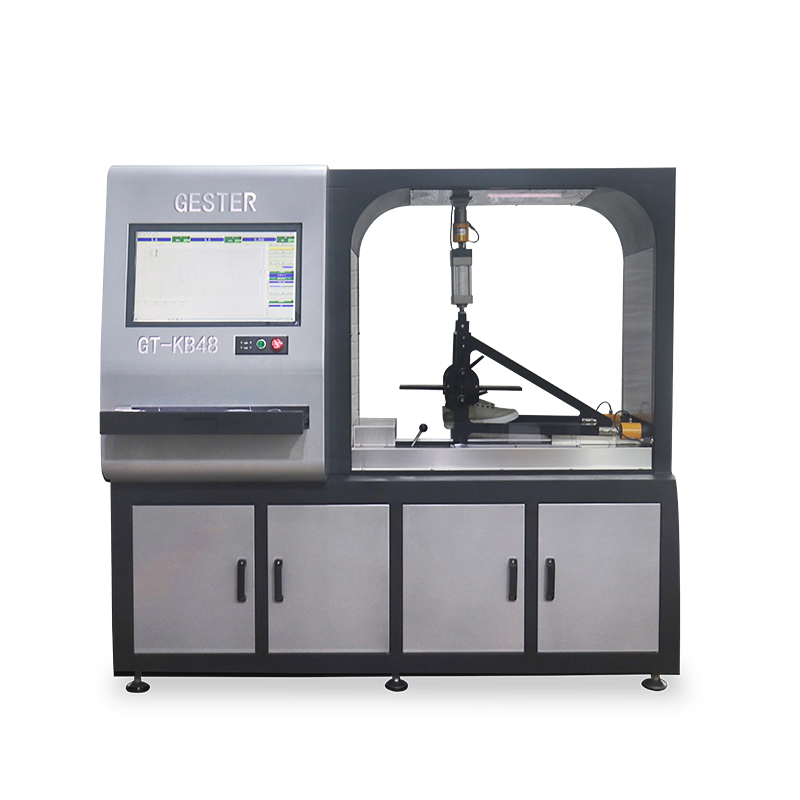

GESTER Instruments introduces some little common sense about shoes. 1. How to distinguish the quality of outsole? There are various outsole material for leather shoes, such as polyurethane, modified polyvinyl chloride etc. The property of flex resistance, abrasion resistance and hardness of outsole are all specified in national industry standard. When choosing the shoes, the outsole should be with elasticity when pressed. And check if any small piece falling off from the bottom when pulling it. Also, it shouldn’t be sticky when touching, should be soft when bending. The quality failure in outsole is a common phenomenon nowadays, the cracking and massive falling off happen occasionally. The reason why it occurs is coming from the sole manufacturer, pursuing more profits and regardless of the quality, which makes the quality failure. GESTER owns below testers for the performance of that: Shoes Flexing Tester GT-KA01-3, EN Sole Flexing Tester GT-KB06. 2.How to distinguish the quality of steel shanks? What is the function for it? Each leather shoes exists one piece of steel shanks, except flats and wedges. It is installed between the outsole and the midsole of the sole and It is the backbone of the shoe, which maintains the bottom curvature and stabilizes the heel. The standard requires the performance of Longitudinal bending stiffness and hardness. When picking shoes, you can use your hand to press the foot part of the shoe moderately, the best condition is that is will not becoming soft or deformed. After wearing, if you find that the heel is skewed or feeling uncomfortable, you can check whether the hook is broken or not. The application: Steel Shanks Stiffness Tester GT-KB46 3. Why leather shoes are always with low glue-intensity? It’s very common that adhesive leather uppers and bottoms are not firmly bonded. There are many reasons for unglued, mainly due to the selection of raw materials in the factory and improper control of the process. The rubber sole and the leather can be glued with neoprene, and the imitation leather bottom and the polyurethane bottom with more resin components are difficult to be effective, and it is necessary to use a polyurethane finger glue or other adhesive to adhere. Because an adhesive is not suitable for any material. Before the bonding, the sole and the upper should be ground and raised, multi-passed and baked, and pressed with a press to bond. The adhesion to the shoes is the peel strength. The adhesion of leather shoes is controlled by the peel strength index, which is measured by GT-KC41 Shoe Peeling Strength Tester. 4. Is it reliable to use cardboard as insole ? In the past, the insole of leather shoes was made from pig and cow bottom leather. Natural leather resources are now reduced. Substitute materials are used to replace certain natural materials. Insole cardboard for shoes is widely used at home and abroad. The shoe insole with good quality have hygroscopicity, gas permeability, flexing...

View More