GESTER Demonstrates High-Quality Testing Equipment to Visiting Indonesian Partners

February 28, 2025

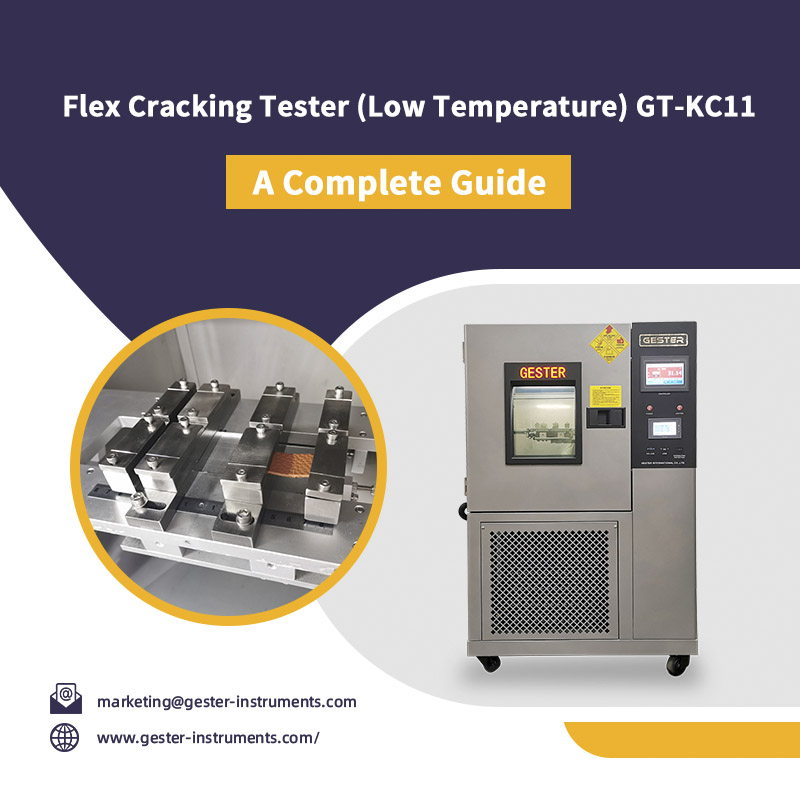

GESTER Demonstrates High-Quality Testing Equipment to Visiting Indonesian Partners In a significant move to strengthen international partnerships, GESTER, a leading provider of advanced testing equipment, recently showcased our latest offerings to a delegation of Indonesian partners. This event highlighted GESTER’s commitment to providing high-quality, reliable, and innovative solutions for industries requiring precise testing and measurement capabilities. A Growing Partnership with Indonesian Markets The Indonesian market has seen substantial growth in industries such as textiles, footwear, and manufacturing, creating a need for accurate and dependable testing instruments. By aligning Indonesian partners' needs with GESTER’s expertise, both sides recognized the potential for enhanced collaboration and continued success in the region. A Look into GESTER's Product Portfolio GESTER’s product portfolio is vast, covering a range of testing equipment designed for different sectors. During the demonstration, We presented several key products tailored to meet the needs of Indonesian industries. Some of the key machines included: Universal Testing Machines (UTMs): These versatile machines can be used across various industries, including textiles, plastics, and electronics, to test the mechanical properties of materials. The UTMs demonstrated are capable of conducting tensile, compression, bending, and other mechanical tests with precision and reliability. Footwear Testing Equipment: For the footwear industry, GESTER’s range of testers, such as the flexing testers and wear testers, provide valuable insights into the durability and performance of shoe materials, helping companies improve the overall quality of their products. Environmental Testing Chambers: These chambers simulate various environmental conditions, such as humidity, temperature, and UV exposure, to test how products behave under extreme conditions. They are especially beneficial for manufacturers in sectors like automotive, electronics, and textiles. Each machine was demonstrated with a detailed explanation of its functions, capabilities, and applications, highlighting how these tools could improve the overall product quality and meet international testing standards. Building Stronger Ties for Future Collaboration By fostering closer relationships, GESTER aims to provide better customer service and support, ensuring that our testing equipments continue to meet the evolving needs of the region. Moreover, GESTER’s local presence and strong customer support network make it well-positioned to serve the Indonesian market for years to come. The Role of Testing Equipment in Enhancing Quality Assurance In today’s competitive global market, ensuring the quality and safety of products is more important than ever. Manufacturers are under pressure to meet rigorous standards, both locally and internationally. Testing equipment plays a crucial role in this process, allowing companies to evaluate their pr...

View More