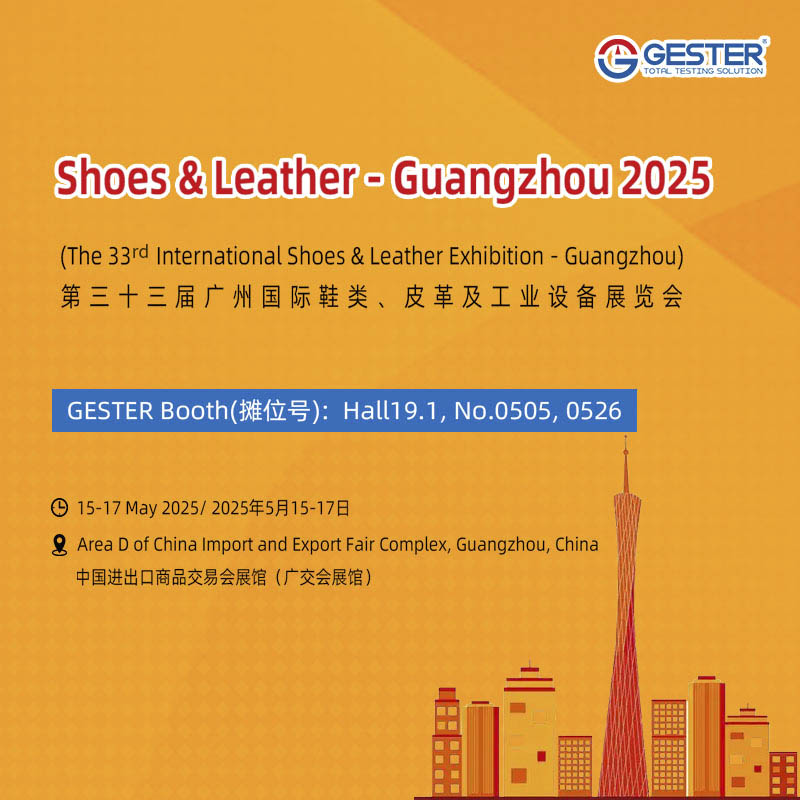

GESTER Invites You to Experience Footwear Testing Equipment at Shoes & Leather Guangzhou 2025

April 28, 2025

GESTER Invites You to Experience Footwear Testing Equipment at Shoes & Leather - Guangzhou 2025 The Shoes & Leather - Guangzhou 2025 has gained industry recognition and become a premier global footwear and leather exhibition where domestic and international enterprises vie for participation opportunities. It serves as an ideal platform for enterprises to showcase the latest fashion trends in footwear and industrial equipment. The exhibition will be held from May 15 to 17, 2025 at Area D, China Import and Export Fair Complex in Pazhou, Guangzhou. GESTER will be located at Hall 19.1, Booths 0505 & 0526, showcasing our latest R&D achievements in footwear testing instruments and solutions. We cordially invite industry partners to visit our booth for technical exchange and business discussions. About GESTER The quality and performance of footwear products have become the key for brands to win the market, and GESTER has developed a full range of high-precision footwear testing equipment with years of technology accumulation, providing the industry with a full range of testing technologies: Whole Shoes Flexing Tester GT-KA01-2 The whole shoes flexing tester is used to test finished shoes, like sports shoes, casual shoes, work shoes etc. And determine its flexibility resistance or indicating the cracks of shoe or shoe sole through reciprocating flexing movements under the specified angle and frequency. EN Sole Flexing Tester GT-KB06 This EN Sole Flexing Tester bennewart flexing machine is used to measure the flexing resistance of shoe soles under continuous movement. Before test, plunge some holes at the maximum bending position, and mount specimen at both grips, one fixed, one movable. Specimen runs flexing owing to the movement of machine. After a certain test cycles, remove the specimen and check its difference of incision length. Universal Testing Machine for Footwear (Dual Column) GT-K01 It is a basic equipment of quality control, receiving inspection, physical test, mechanics research, material development. Taber Abrasion Resistance Test Machine GT-C14A The taber abrasion testing machine is used to determine the wear resistance of materials and assess its wear resistance degree, like measuring its mass loss, thickness loss, and transmittance etc. Bally Leather Flexing Tester GT-KC10A This Bally resistance flexing tester is used to determine the resistance of a material to cracking or other types of failure at flexing creases. The method is applicable to all flexible materials and in particular leathers, coated fabrics and textiles used in footwear uppers. Exhibition Interaction GESTER's footwear testing instruments combine user-friendly operation with precision accuracy, and have passed many international certifications such as ISO, ASTM, etc. GESTER has become the preferred testing partner of many international famous sports brands. During the exhibition, we will demonstrate the following: On-site Product Demonstration: Our technic...

View More