Commonly used equipment for leather physical testing (一)

October 21, 2020

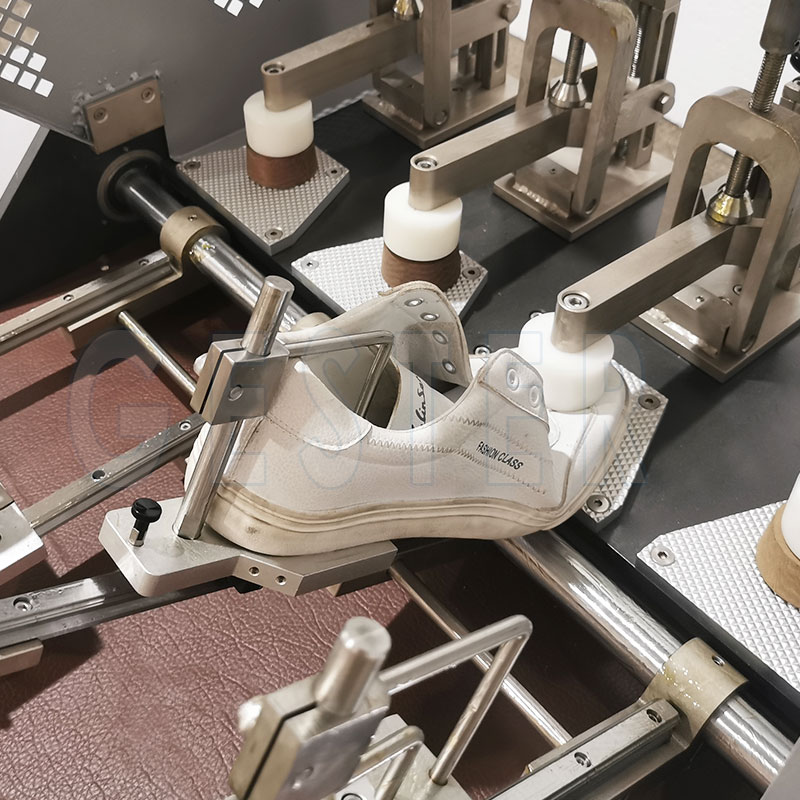

Leather physical testing mainly includes: tensile strength, elongation, tear strength, composite peel strength, abrasion resistance, folding fastness, color fastness (the color also includes dry rub resistance, wet rub resistance, Sweat resistance, heat resistance, water fastness, washing resistance, stain resistance, etc.), air permeability, water permeability, dynamic water resistance, softness, horizontal flammability, atomization, odor, etc. Related Leather testing equipment commonly used is described as follows: 1. The leather yellowing resistance tester (UV Light Discoloration Tester GT-KD02)is used to determine the yellowing resistance of white or light-colored state materials, substrates, leather, PU, fabrics and other shoe materials to light exposure. It uses solar light bulbs and heating temperature control devices. Irradiate the sample to test its resistance to yellowing under sunlight. 2.The leather softness tester is used to measure the softness of leather and animal skins to understand whether the softness and hardness of the same batch of leather is uniform, or the softness difference of each part of a single piece of leather. Accurate, beautiful, easy to operate and maintain, and portable. 3. The Leather Flexing Tester is used to test the flexure resistance of thin leathers such as shoe uppers, clothing, leather, bags, etc. The test principle is that one end of the test piece is used as the inner side and the other end surface is used as the outer side to be reciprocally bent. Record the number of bending when the test piece is damaged. (Note: This test method has two different methods: normal temperature and low temperature. Low Temperature Bally Resistance Flexing Tester is used for the cold resistance of leather at low temperatures to understand how the material or finished product adapts to low-temperature climates or cold regions.) 4. TABER leather abrasion tester is suitable for cloth, paper, paint, plywood, leather, floor tiles, glass, natural plastics, etc. The Taber Abrasion Tester test method is that the rotating sample is pressed against a pair of grinding wheels, and the specified load is applied, and the sample is rotated When driving the grinding wheel to provide abrasion test material, the weight loss due to abrasion is the weight difference before and after the test. 5. The Electronic Crockmeter is used to test the degree of decolorization of dyed fabrics and leather by friction. The test method is to wrap a dry or wet white cotton cloth in a friction cone, and then rub the test piece clamped on the test back and forth. Evaluate the color fastness grade. (Note: The test method is different from the leather rubbing abrasion tester in that the difference between white cotton cloth and wool felt is used respectively) 6. Leather dynamic waterproof testing machine is used to test leather, artificial leather, cloth and other materials. Cut test pieces, install them on the testing machine, and apply a flexing action under...

View More