Simple Troubleshooting Of Tensile Testing Machine

November 16, 2021

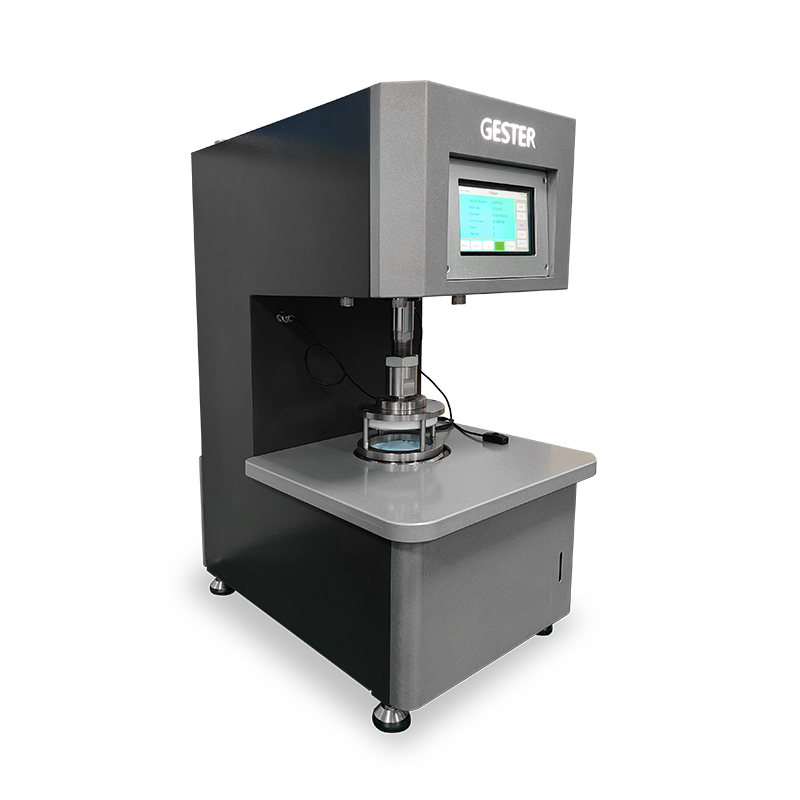

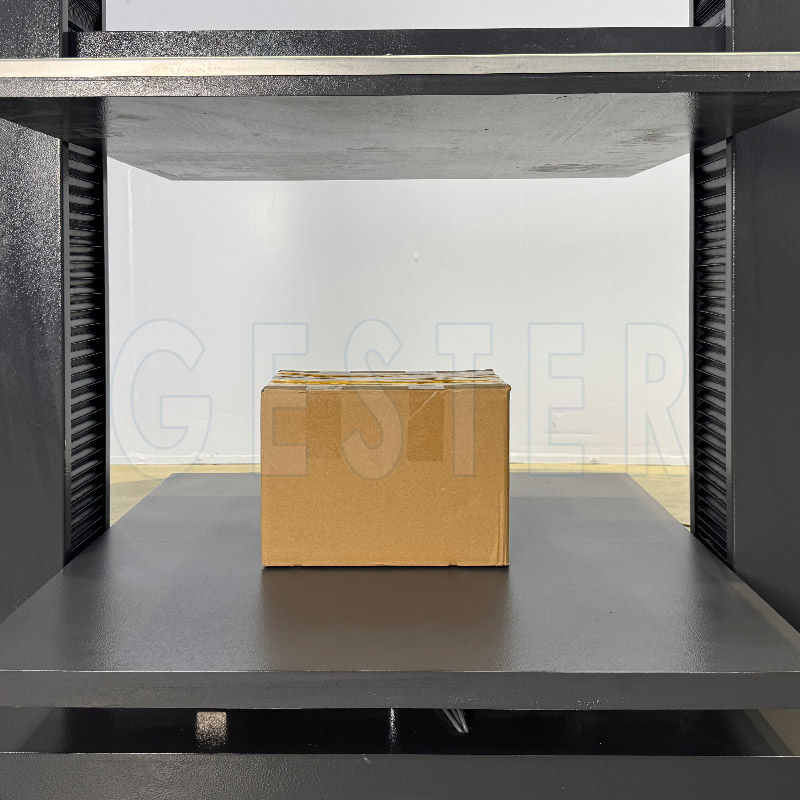

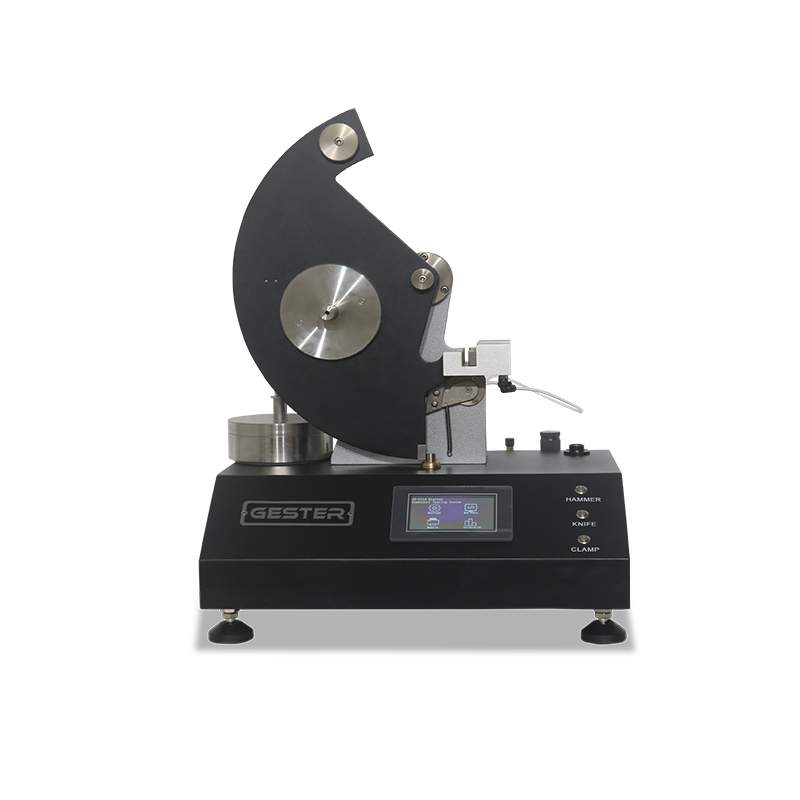

Users in the use of universal material testing machine, sometimes there will be some failures. If the user can deal with the failure in time, it can improve the work efficiency of the enterprise, which is especially important when the project is on schedule. So Gester provides users with some common troubleshooting methods, hoping to help everyone. Solution to the failure of material tensile testing machine: 1. The power supply has electricity but the tensile testing machine can not move up and down. Check whether the power supply voltage of the access material tension tester is normal, check whether the upper and lower limit is in the appropriate position, etc. 2. After the tensile testing machine is online, a prompt box appears indicating overload. Check whether the on-line selection sensor is selected correctly, whether the sensor has been hit by accident, whether the communication line of the tensile testing machine has fallen off, check whether the calibration value has been manually changed, etc. 3. Plug it in and use it for a while, and suddenly there is no reaction. Check whether there is any problem with the wiring, whether the socket is plugged in, or the cable is almost cut off by a mouse, and check whether the power supply voltage connected to the tensile tester is normal. Universal Tensile Strength Tester (Dual Column), developed and produced by Gester Instruments, with high precision, the most perfect function, the most stable performance, cost-effective advantages. Tensile strength equipment Application: This Universal Tensile Strength Tester is designed for conduct tensile, compression, bending, shearing, bonding strength, peeling, tearing and other tests for rubber, plastic, leather, metal, nylon line, fabric, paper, aviation, packaging, construction, petrifaction, electrician, vehicle and other materials. universal testing machine is a basic equipment of quality control, receiving inspection, physical test, mechanics research, material development. Universal material testing machine Standards: ISO13934-1, 13934-2, 13935-1, 13935-2, 13936-1, 13936-2, 13936-3, 13937-2, 13937-3, 13937-4, 1421, 2411, 2062, 4674-1, 5082, 9073.3, 9073.4, 9073.18 ASTM D 434, D751, D885 , D1683, D2256, D2261, D2724, D2731, D3787, D4034, D4964, D5034, D5035, D5587, D5733, D5735 . BS 2543, 2576, 3320, 3424, 4303 , 4304, M&S P11, P12, P13, P14 JIS L1096

View More