Introduction

Understanding the Drop Test

The free fall drop test is a controlled experiment designed to mimic real-world scenarios where packaged items might be dropped or subjected to falls. The aim is to assess how well the packaging material can endure the impact without damaging the enclosed product. This evaluation becomes paramount as it helps manufacturers identify weaknesses in their packaging design and make necessary improvements before products reach consumers.

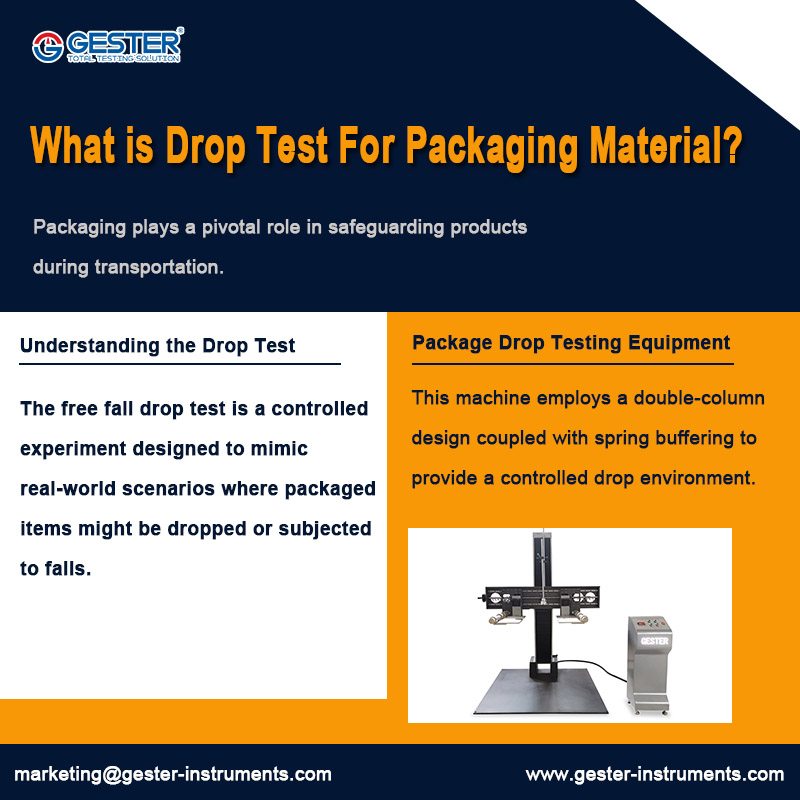

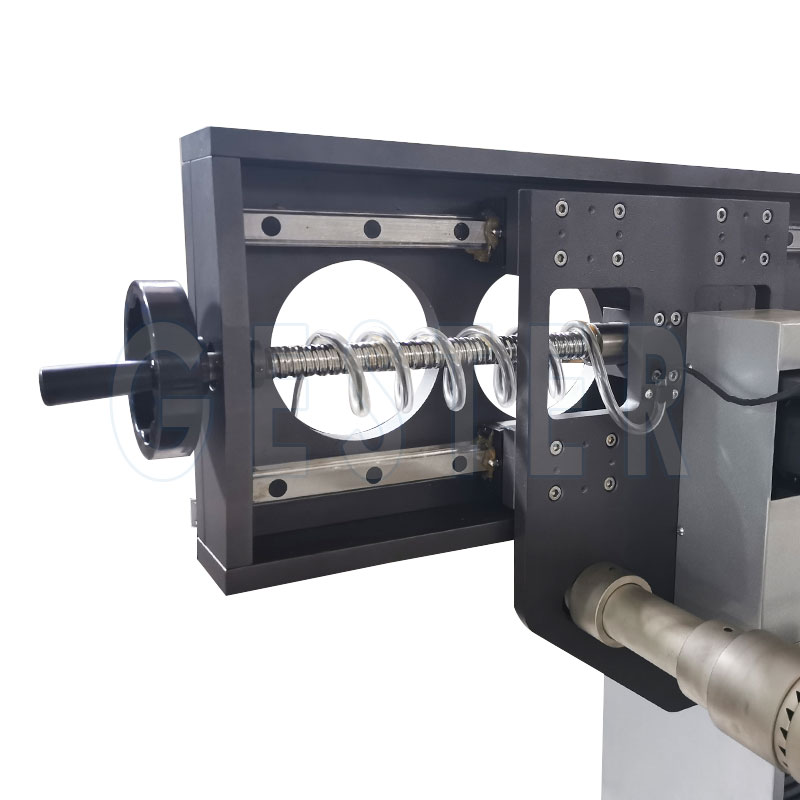

Package Drop Testing Equipment

Applications

Standards and Guidelines

Conclusion