Do you have any embarrassing situation in your clothing that has been broken by a sharp object? In real life, our clothes will be broken and torn when worn, which involves the problem of strong tearing of the fabric. Then what is the tear strength?

Fabric tear

Fabric tearing also referred to as tearing,fabric partial yarn is subjected to a concentrated load to tear the fabric apart. During the use of the fabric, the clothes are hooked by the object, partial yarn is pulled apart by force, so that the fabric forms a strip or a triangular crack, which is also a phenomenon of breakage.

Tear Strength

It can reflect the degree of catalysis of the finished fabric, so the tearing strength test is performed on the resin-finished cotton fabric and the wool-formed pure or blended combed fabric. Knitted fabrics are generally not subjected to tear test except for special requirements.

How to judge if the tear strength of your clothes is qualified or not?

There are many methods for the tear strength test:

1. Pendulum method

2. Pants type method (including single tongue method and double tongue method)

3. Trapezoid method

4. Wing method.

The most common test method is the pant-shaped single tongue tear test. And how to test it?

Cut the sample as belows picture shown according the standard required. Standard require each sample cut into two test sample. One is lengthways. The other one is crosswise. Each test sample should be included at least 5 pieces. Then on test.

When the stressed yarn in the sample is separated up and down gradually, the yarn that is not directly stressed begins to have some relative sliding with the stressed yarn., and gradually draws closer to form an approximate triangular area, which is usually called the stressed triangle.

Due to the effect of friction resistance between the yarns, the sliding is finite, that is, the number of yarn roots under stress in the triangle is limited.In the stress triangle area, the stress on the bottom edge of the first yarn is the largest, and decreases successively.

When it is sliding, the tension of the yarn increases rapidly, the elongation of the yarn also increases sharply. When the first yarn constituting the bottom edge of the force-triangle triangle is deformed to the elongation at break, the yarn breaks. Thereby a maximum value of a certain tear load is obtained. The next yarn then begins to become the bottom edge of the force triangle, so that the yarn of the non-pull system breaks one at a time to tear the fabric.

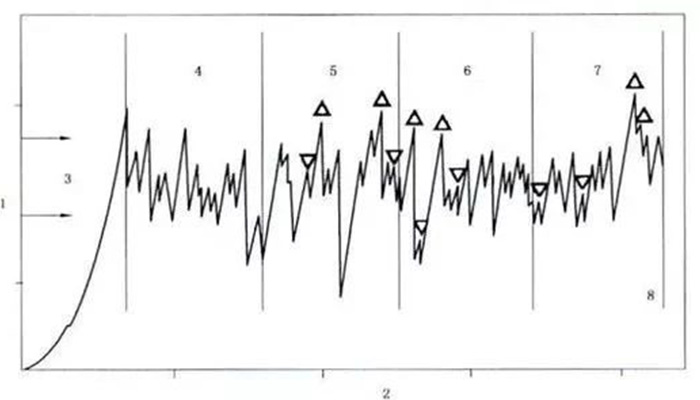

Lastly, the calculating.the electronic calculation devices divides the first peak and the last peak into four regions,exclude the first region, and records all the peaks in the rest of three region. The average value was calculated and the tear strength of this sample was recorded. (The unit is indicated by N)

Testing Equipment: GT-C01-1 Universal Tensile Strength Tester (Dual Column)