Testing of Yarn Twist and Influencing Factors

July 02, 2019

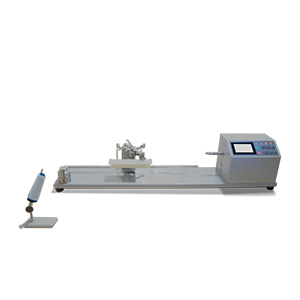

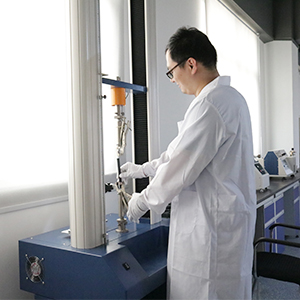

It needs for twisting when you spinning short fibers into continuous yarns.They keep the aggregate force when they stay together, then gives the strength of yarn. Filament in composite filaments also requires mild twisting. It will be dislodged or scratched in use if they are not tied together. In addition, according to various kinds of applications, plurality of single yarns can be combined and twisted to become plied yarns and cables, to make them keep uniform and stable for sustaining higher load. When at least two yarns twist with different speeds and tensions, or twist with different colors or fancy yarns, they can form fancy yarns. Twisting is a method of bringing bundle fiber, filament yarn, and single yarns together. It can help textile bears force, change and rub in production and in use. And gives textile fresh appearance. 1.Concept of Twist As well as affecting the tensile performance of the yarn, the twist also will affects the diameter, specific volume, softness and stiffness of yarns, affecting the covering performance, heat retention, crease recovery, dyeing rate and permeability of the textile. It also affects the hairiness of the yarn surface. Twist is an important indicator of the structural characteristics of the yarn. In addition to the twist and twist multiplier can be expressed, the twisting direction of the yarn is also important. It refers to the tilting direction of the yarn when adds twist. There are two types of twist: S-plied(twist to the left) and Z-plied(twist to the right). Most manufactured single yarns are spun with a Z twist.To ply these Z-plied together, they are twist with an S twist to give a balanced plied yarn. 2.Methods of Twist Testing There are 2 commonly testing methods: direct counting method, Untwist-retwist method. The short fibers and plied yarns commonly use the direct counting method, while the spun yarns use Untwist-retwist method. Besides, they are Double untwist-retwist method, Double untwist-retwist method and Sliding method. (1.)Direct counting Fixed the one side of sample,another one at one rotating direction of untwisting.When the fibers in the yarn are completely parallel, and the degree of retraction is the number of turns of the length on this sample. The direct counting method is the basic method. The measurement results are relatively accurate and often used as a criterion for assessing the accuracy of other methods.However, this method is inefficient in operation. If the fibers in the yarn are kinked, the fibers can not easy to become parallel, and the fibers are easy to broken. The direct counting method is generally used to count the number of rovings or plied yarns. For spun yarn, it can be carried out by black and white yarn number method. It means that a black roving and a white roving are used to feed the same yarn to spun the black and white yarn. With the increase of remove twist, the distance will become larger between the black and white on the yarn, and easy to manuall...

View More