What Is The Test Method Of The Cornell Mattress Fatigue Testing Machine

July 19, 2022

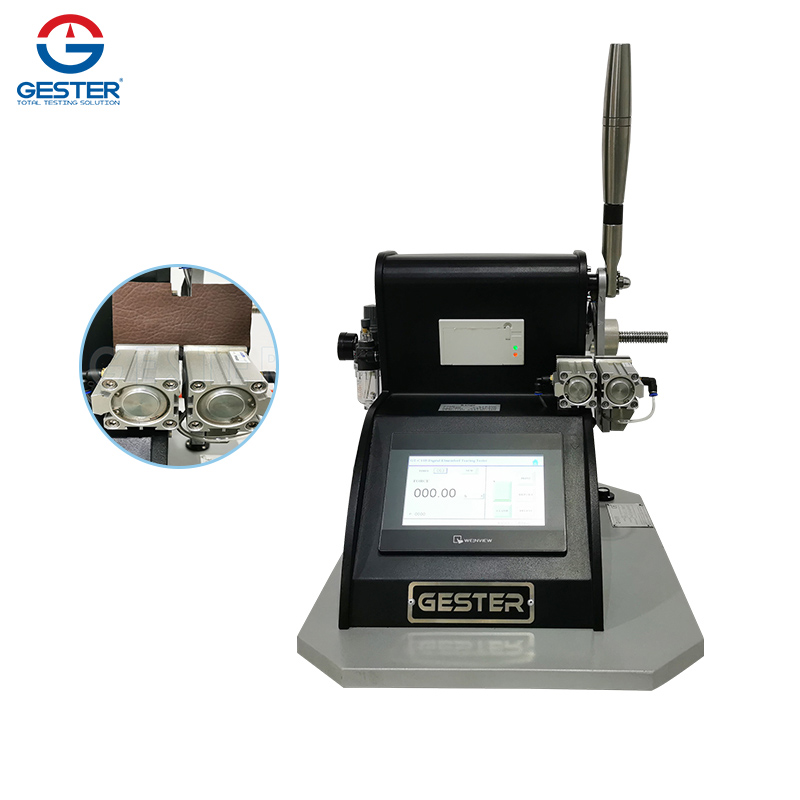

What Is The Test Method Of The Cornell Mattress Fatigue Testing Machine Mattress Spring Fatigue Tester/ Cornell Tester is applied to test the endurance capacity under the long-term repetitive load and the compression deformation for the mattress.Accord with the standard ASTM F 1566. With sofa Cornell fatigue life test method, motor drive eccentric wheel, adjust the impacting height of the impact block, then impact the testing mattress by 120-160 times / min, counter measures the impacting times, shut down automatically when reaches the setting times. This instrument is composed of two cooperating test systems, one is the impact fatigue test system (controlled by PLC), and the other one is the deflection test system (controlled by computer software). ASTM F 1566 Mattress Spring Fatigue Tester Operation 1.Before Furniture tester Mattress Spring Fatigue Testing 1.1 Prepare the mattress or mattress sets to be tested and mark the test location, according to the standard. 1.2 Install the power supply as required, and connect the computer and the machine. 2.Mattress Spring Fatigue Tester Operating Steps 2.1 Turn on, enter PLC Interface, Install mattress, adjust the position of the hammer, make it points to test location. 2.2 Tum on control box and computer. 2.3 Click "English" to enter the test interface, click "TOP" to make impact head returm to the top point. 2.3.1 On ProjectSelect, choose first one,ASTM F1566 Cornel,Test 1 Step. Click "Zero" , start testing, when test done, "Save data?"appeared, click "save" test result automatically, on test Result, you can see result value. This value divided by 2,you can get radius of rotation, adjust the impact head with the obtained radius of rotation.Use spanner unscrew it.There is scale line, use another spanner to adjust it. Click UP", make impact head don't touch the mattress. 2.3.2 On ProjectSelect, choose second one,ASTM F1566 Cormel,Test 2 Step, start test. When test done, "Save data?appeared, click "Cancel” , don't need to save this value. Set test parameters on PLC, including the total test cycles, segment test cycles, test speed.Click "START" to runnina. When the segment test cycles is done(100 cycles), the PLC will pause. 2.3.3 On computer, User Settings, choose ProjectSelect, choose third one, ASTM F1566 Cormel, Test 3 Step. Click Zero , " Test to start testing.When test done,"Save data?"appeared, click "Cancel” , don't need to save this value. 2.3.4 On computer, User Settings, choose ProjectSelect, choosefourth one,ASTM F1566 Cornel,Test 4 Step. When test done,"Save data?" appeared, click "save , to save this value. On testResult, you can see result value. On ResultSelect, select "ASTMF1566 Test 4 Step", you can get all values. Result value resolution: When it deform 12.7mm, the force is 240.10N;When it deform 25.4mm, the force is 607.18N;

View More