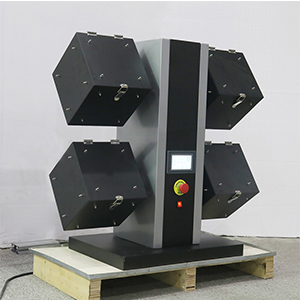

Correct use of colour matching light box

October 25, 2019

In daily experiments, when colour matching light box are used, some of them do not conform to the standard on color due to some details, which will cause adverse effects on subsequent production. Here are 7 key steps that you can take to use a colour matching light box. Key step 1: Observing the angle According to international standards, only two observation angles are available, they are: a. Zero-degree light source, 45 degree observation (0°-45°) that the light source illuminates the sample from a zero (vertical) angle of incidence, and the observer observes the sample from 45 degrees. b. Light source, 45° ramp. 45 degree light source, zero degree observation (0°-45°), in this layout, a specific 45 degree angled table (45°Fixed angle table) is used to illuminate the light source from the 45 degree, and the observer observes from zero (vertical) sample. Key step 2: 45 ° light source detection sample placement Regardless of any of the above observation methods, care must be taken to detect the sample as much as possible in the middle of the color matching booth to reduce the effects of the external light source. In addition, the most important thing is that when you need to compare the color of two or more objects, you should also try not to overlap them. It is best to place them side by side for comparison. Key step 3: environmental factors in color All external light that will have the opportunity to shine on the test sample must be avoided. If the window is in the field of view, it should also be covered with grey curtains to cover it, so it is ideal to use a color light box in the black room. Another point that is often overlooked is that no other debris can be placed on the color light box. Key Step 4: Requirements for Converting Light Sources According to the experience of daily life, in our eyes, it is like having a register. When the color changes in a very short time, we can clearly feel it. Therefore, when observing metamerism, if you want to change the light source, you must do it in an instant. Don’t be like the lighting tube we use every day. It will be high after a flash, because it will irritate the eye. Department, affecting the results of the review. Key step 5: Ability to test metamerism The so-called metamerism effect means that under a certain light source, the color displayed by the sample is the same as the requirement, but under another light source, the color difference is not acceptable. Under the D65 light source, the color is no different from the standard, but under A light, the sample color is unacceptable. Therefore, all devices for color light sources must be equipped with two or more light sources to test the same color effect. Key step 6: arrangement of the lamps Although there is no specific requirement for the arrangement of the lamps, the position of the lamps must be a uniform light source in the color matching cabinet, and must not be biased to a certain area. Key Step 7: Record the time used by the standard...

View More