Standard test method for fastness to sunlight of fabrics

October 17, 2019

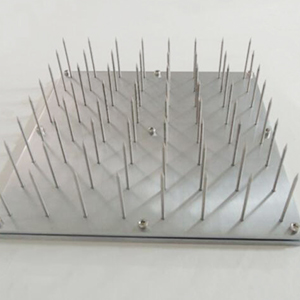

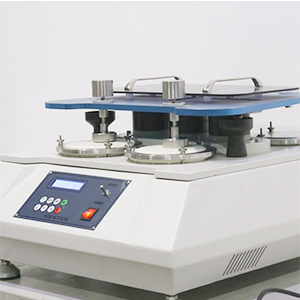

The light fastness refers to the degree of lightfastness of the dyed fabric, that is, the degree of discoloration and discoloration of the dyed fabric under the illumination of sunlight or artificial light sources.Sunlight fading is a relatively complicated process. Under the illumination of light, the dye absorbs light energy, and the molecules are decomposed or rearranged to cause discoloration and discoloration. The fading mechanism is different, such as the fading of azo dyes on cellulose fibers, mainly due to the oxidation of dyes by air under the illumination of light, and its fading on protein fibers is often the result of reduction. According to international standards, the light fastness is divided into 8 grades, the lowest grade 1 is equivalent to fading after exposure to sunlight for 3 hours; the highest grade 8 is equivalent to fading at 384 h after exposure to sunlight. The evaluation method is based on the comparison of the blue wool standard. The standard is a wool fabric dyed with 8 different light fastness blue dyes, and the degree of solarization between them is geometrically spaced. That is, level 2 sun 57 h, level 3 sun 112 h, level 4 sun 166 h, level 5 sun 220 h, level 6 sun 275 h, 7 level sun 329 h. Under normal circumstances, the light fastness can reach 4, and the special requirements for high light fastness can reach 5 levels. However, in the actual test, since the intensity of the sunlight is unstable, the test results are also different, so the artificial light source (the xenon arc lamp, the carbon arc lamp) is used to test the light fastness. The general methods are now GB/T8427-1998 "Test Method for Xenon Arc Lamps"; ISO 105-B01-1994 "Textile Fastness Test Part B01: Light Fastness", ISO 105-B02-1994 "Textile Colors" Fastness test Part B02: Resistance to artificial light fastness Xenon arc lamp fading test, ISO 105-B05-1993 "Texture fastness test of textiles Part B05: Detection and evaluation of photochromism"; AATCC139-2000 "Lightfastness" Color fastness: detection of photochromism, AATCC 169-2003 "Textile weatherability: Xenon arc lamp irradiation"; JIS L 0841-2004 "Sunlight fastness test method", JIS L 0842-2004 Test method for dyeing fastness of ultraviolet carbon arc light, JIS L 0842-1998 "Test method for dyeing fastness of xenon arc resistance". Recommended test equipment: GT-3000 Light Weather Fastness Tester GT-D01 Suntest & Xenon Arc Testers GT-D01B Colorfastness to Ozone GT-D02A-1 Light Fastness Tester-RT GT-D02C Carbon Arc Lamp Colorfastness to Weathering Tester

View More