Brand:

GESTERItem NO.:

GT-F56Order(MOQ):

1Payment:

T/T, L/CLead Time:

25 daysProduct Detail

|

Application: This thermal shck test equipment is prohibited to flammable, explosive, easy to volatile substances sample test or storage, corrosive substance sample test or storage, biological sample test or storage, strong electromagnetic emission source sample test or storage. |

|

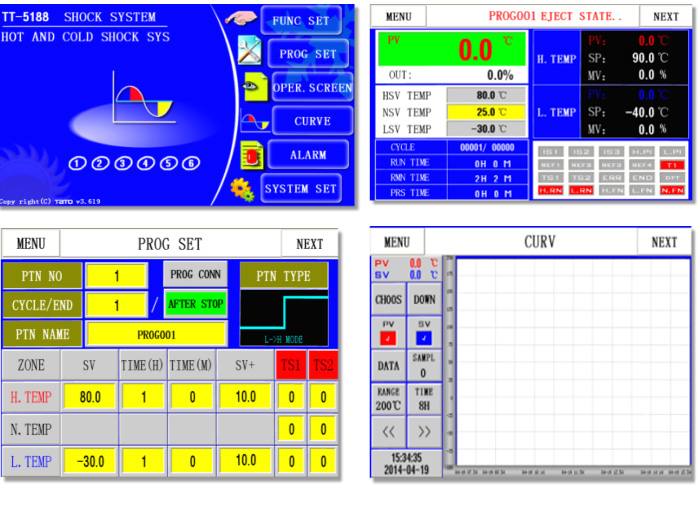

Temperature range of test area |

-40℃~150℃, -60℃~150℃, -65℃~150℃ ( option) |

|

High temperature range: +60℃~150℃ |

|

|

Low temperature range: -10℃~150℃ |

|

|

Testing environment condition |

Environment temperature: +28℃ Relative humidity: ≤ 85% In the condition of without sample in the sample chamber |

|

Preheating temperature range |

+60℃~+150℃ |

|

Heating up time |

+60℃→+150℃ ≤ 40min Note: The heating up time is the performance when the high temperature chamber individually operates. |

|

Low temperature chamber |

Note: The heating up time is the performance when the high temperature chamber individually operates. |

|

Precooling temperature range |

-55℃~-10℃ |

|

Cooling time |

+20℃→ -55℃≤ 70min Note: The cooling time is the performance when the low temperature chamber individually operates. |

|

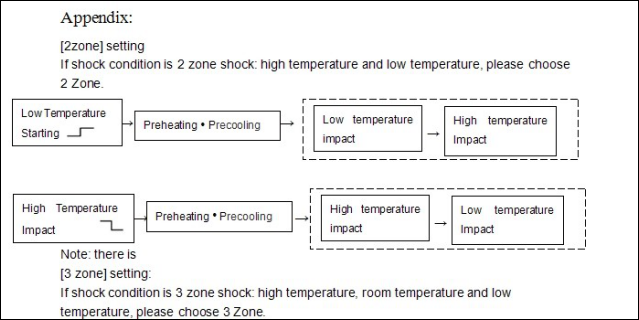

Testing method |

Switch pneumatic ventilation door 2 or 3 temperature zones. |

|

Temperature shock range |

-40℃~+150℃ |

|

Temperature fluctuation |

±0.5℃ |

|

Temperature departure |

±2.0℃ |

|

Temperature recovery time |

≤ 5min |

|

Recovery condition (Chart One)

|

Sample: plastic packaged integrated circuit(uniformly distribute) Sensor: the upper side of the sample High temperature exposure: +150℃ 30 minutes Environment temperature exposure: --- Low temperature exposure: -40℃ 30 minutes Sample weight: 2.5kg |

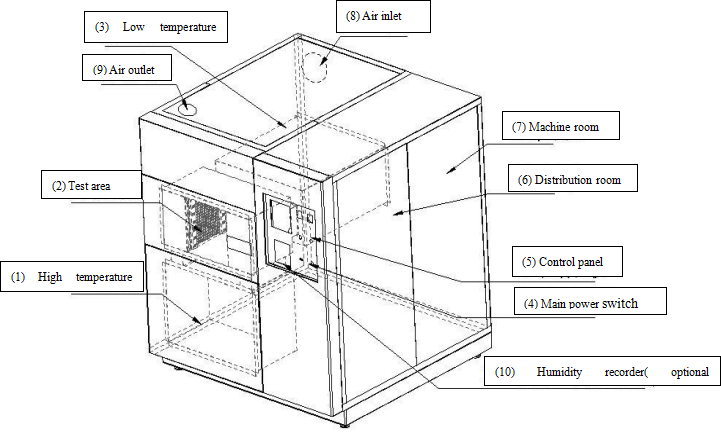

1. Heat preservation envelop enclosure:

4. load capacity of test chamber basket (uniform distribution),

2 sample basket, 5kg load capacity each(uniform distribution).

5. Adjusting foot and adjusting wheel: 4 adjusting feet to support the test chamber, 4 adjusting wheels to move the test chamber.9. Thermal shock test machine room: Refrigeration unit, drainage device, exhaust fan.

10. Power distribution control cabinet: main power leakage circuit breaker, controller, power distribution board, cooling fan, high and low temperature circle back fan motor.

11. Heater: Nickel chromium alloy strip heater,